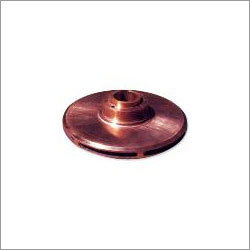

Kirloskar Pump Impeller

Price 200-200000 INR/ Piece

Kirloskar Pump Impeller Specification

- Shape

- Round

- Part Type

- Casing Cover

- Material

- ss

- Usage

- Air Pump

- Product Type

- Pump

- Application

- Sewage

- Theory

- Axial Flow Pump

- Color

- Grey

Kirloskar Pump Impeller Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Kirloskar Pump Impeller

We are among the most respectable firms, involved in manufacturing, supplying and exporting Kirloskar Pump Impeller. These products are widely demanded by engineering, chemical, petrochemical, pharmaceutical and textile industries. Also, we stringently test all the products on various parameters to assure flawlessness. We also make use of quality packaging material to pack our Kirloskar Pump Impeller. Further, we keep a stock of all impellers to meet customers' urgent needs.

Features:

-

Dimensionally accurate

-

Hard-wearing performance

-

Zero maintenance

Engineered for Demanding Sewage Applications

The Kirloskar Pump Impeller stands out for its adaptability in sewage systems and industrial air pumps. Its axial flow design facilitates optimal fluid transfer, making it invaluable for managing wastewater in large facilities. The round shape and sturdy ss material ensure resilience against corrosive agents, which translates into extended operational life and low downtime.

Reliable Distribution Across India

Available through a network of distributors, manufacturers, exporters, suppliers, and traders throughout India, the Kirloskar Pump Impeller is easily accessible for industrial users seeking high-quality pump components. Its consistent availability ensures timely replacement and maintenance support, reducing unexpected system interruptions.

FAQs of Kirloskar Pump Impeller:

Q: How is the Kirloskar Pump Impeller installed in industrial sewage systems?

A: The impeller is installed within the pump casing, acting as a casing cover. Its round, stainless steel design fits standard industrial sewage and air pump assemblies, facilitating easy integration during maintenance or new system setups.Q: What are the advantages of using a stainless steel (ss) impeller in sewage applications?

A: Stainless steel provides superior corrosion and wear resistance, especially important in sewage systems exposed to harsh chemicals and solids. This ensures longer service life and reduced maintenance costs.Q: When should the Kirloskar Pump Impeller be replaced?

A: Replacement is recommended when there is significant wear, reduced pump efficiency, or visible damage due to abrasive materials handled in sewage or air pumping operations. Regular inspection ensures timely replacement for optimal performance.Q: Where can I source Kirloskar Pump Impellers in India?

A: Pump impellers are available through authorized distributors, suppliers, manufacturers, exporters, and traders spread across India. Contacting these channels guarantees access to genuine components and warranty support.Q: What is the process of selecting the correct impeller for an axial flow pump application?

A: Choosing the right impeller involves matching the pumps operational parameters with the impellers size, shape, and material. For axial flow applications in sewage or air pumps, round stainless steel impellers are preferred for their durability and flow efficiency.Q: How does the axial flow theory benefit sewage pump operations?

A: The axial flow theory enables fluid to travel parallel to the pump shaft, optimizing energy efficiency and ensuring high-volume flow rates. This is especially beneficial for managing large amounts of wastewater quickly and effectively in industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pump Impellers Category

Metal Pump Impeller

Price 200-200000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Air Pump

Application : Sewage

Material : ss

Part Type : Casing Cover

Designed Pump Impeller

Price 200-200000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Air Pump

Application : Sewage

Material : ss

Part Type : Casing Cover

KIRLOSKAR PUMP SEMI OPEN IMPELLER

Price 200-200000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Air Pump

Application : Sewage

Material : ss

Part Type : Casing Cover

Stainless Steel Pump Impellers

Price 200-200000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Air Pump

Application : Sewage

Material : ss

Part Type : Casing Cover

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS